Patterns, Molds & Tooling

Vacuum Forming Product Development

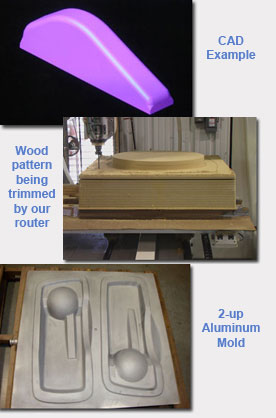

To ensure accuracy and repeatability for your plastic formed part, we create wood patterns used to cast aluminum moldings. The aluminum molds are used throughout the production process; or if you prefer, we also have inexpensive wood and epoxy molds available. Once you have reviewed our design parameters and your design is complete, we are then able to begin the tooling process.

As thermoformers, we incorporate the use of 3D images (CAD/CAM and solid models) to support the creation of production tooling. If you have your part designed in CAD, we will be able to import your engineering files and lower your cost. If needed, our in-house programming team can generate the 3D model based upon your designs. As thermoformers, we incorporate the use of 3D images (CAD/CAM and solid models) to support the creation of production tooling. If you have your part designed in CAD, we will be able to import your engineering files and lower your cost. If needed, our in-house programming team can generate the 3D model based upon your designs.

The CAD/CAM files are then used to produce a wood pattern on one of our CNC routing machines . Next, the wood pattern is used to manufacture an aluminum mold. In building an aluminum mold we compensate for the inevitable shrinkage of the plastic part; this is typically 0.5% to 3.0%. Additionally, we compensate for the shrinkage of the aluminum casting which is typically 1.1% to 1.3%. So our wood patterns would include 1.6% to 4.3% oversize calculation as compensation for these shrinkages.

Being experienced plastic molders, we can provide prototypes before thermoforming production begins to ensure you are getting the perfect part.

To support your plastic thermoforming needs to the fullest, our internal engineering and programming departments can be involved in your design process. We can make a thermoform program or trim component modifications quickly to facilitate your vacuum forming requirements. To support your plastic thermoforming needs to the fullest, our internal engineering and programming departments can be involved in your design process. We can make a thermoform program or trim component modifications quickly to facilitate your vacuum forming requirements.

We can handle all aspects from engineering and CAD development to production and logistics. Contact our plastic molders today with any questions concerning your vacuum forming needs.

|